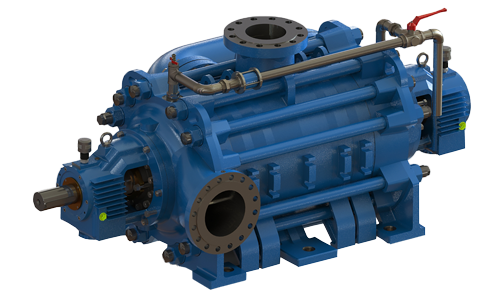

GSB Range

The self balancing multistage pump by virtue of its design completely eliminates any of the threats posed by axial thrust.

Self Balancing Mutli-Stage Centrifugal Pump

High Lift, High Volume - Multistage Clear Water Pumps

The Grifo Self Balancing multistage centrifugal pump units are suitable for pumping clear water at a maximum temperature of 105°C. They represent a major advance in high lift multi-stage pump technology and are designed to meet the stringent demands of modern day mine dewatering methods. Scamont Engineering manufactures four different pump models for effective operation under varying conditions.

GSB250

Operates at 1490 rpm, pumping to heads of 1 460 metres at a volumetric output of 260 litres per second.

GSB200

Operates at 1490 rpm, pumping to heads of 1 211 metres at a volumetric output of 143 litres per second.

GSB 150

Operates at 1490 rpm, pumping to heads of 614 metres at a volumetric output of 65 litres per second.

GSB 150

Operates at 2980 rpm, pumping to heads of 2 035 metres at a volumetric output of 130 litres per second.

- Pump components can be supplied with ceramic or other coatings, preventing damage in locations where poor quality water is pumped.

- Costly intermediate pump stations are no longer necessary in the construction of new shaft systems.

Refurbishment cost of GSB pump units is significantly reduced due to the minimal axial and radial thrust of the rotating element. - Physical dimensions of the GSB pump unit are similar to existing pump units and only minor foundation and piping alterations are required for installation of the GSB unit.

- The units are maintenance free, thus pump stations can be fully automated, significantly reducing operational, maintenance and labour costs over the entire life of the mine.

The pump units are robustly constructed to withstand the harshest mining environments, and incorporate modern hydraulic design principles.

Conventional balancing discs and the associated maintenance problems are completely excluded by fitment of opposing impellers on either side of the centre casing section which eliminate hydraulic thrust.

Spun cast bronze impellers ensure mechanical and metallurgical integrity.