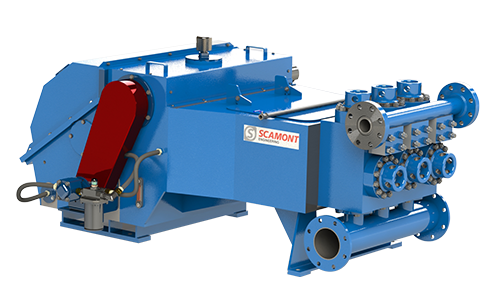

Triplex PD SP200

First launched in 1984, this pump is regarded as the bechmark for high pressure pumping applications across multiple industries.

SP200 - Single Acting Reciprocating Plunger Sludge Pump

The benchmark for high pressure pumping applications

First launched in 1984, the Scamont SP200 pump is regarded as the benchmark for high pressure pumping applications across multiple industries. The most common application of the Scamont SP200 is in the mining industry where the removal of mud, sludge and dirty water from underground is of critical importance.

The Scamont range is the most advanced in the positive displacement mud pump class because it incorporates innovative design features with proven mechanical technology. The pump casing is made from fabricated steel and stress relieved before machining, thus providing exceptional rigidity. The split-casing design allows for quick and easy maintenance and refurbishment to be carried out more effectively and efficiently than previous generation pumps. This includes the ability to replace bearings and gears with minimum effort.

Specifications

Recommended Motor Size: 110 kW

Larger motors can be installed however maximum pressure cannot be exceeded.

Recommended NPSHr: 9.8kPa (gauge)

Suction lines longer than 6m will result in a greater NPSHr.

Please contact a Scamont representative to assist.

Pump Monitoring Device

Scamont offers a lubrication and heat monitoring system which trips the pump on low oil, filter block or oil temperature limit.

Materials of Construction

Scamont Engineering can alter the materials of construction for any application including mud and acid water.

Curves

For further information regarding the performance and general arrangement of the Scamont SP200 please contact Scamont Engineering directly.

Optional Features

- Advanced coating to plungers such as chrome or tungsten

- Stainless steel valves seats and bumper assemblies

- Mechanical stuffing box seals

- Electrical oil protection systems

- Fully integrated starter panels including bypass control, level control, motor protection and early warning systems

- External electric powered lubrication pump

- Oil heat exchanger cooling systems

- Flame hardened main gear and heat treated alloy pinion gear sets

- Forged alloy fluid ends

- Actuated bypass valves

- Fabricated skid

- Either electric or diesel driven

| Pump Configuration | Displacement (l/s) | Max Pressure (MPa) |

|---|---|---|

| SP200 3" | 4.63 | 20.7 |

| SP200 3.5" | 6.3 | 15.8 |

| SP200 4" | 8.23 | 12.01 |

| SP200 4.5" | 10.42 | 9.55 |

- High dynamic head applications

- Horizontal or vertical transfer

- Underground and surface mining operations

- Settler underflow

- High pressure jetting or hosing

- Shaft bottom de-watering

- Stage mounting during shaft sinking

- Backfill pumping

- Grout plants

- Tailings

- Robust design with fabricated steel frame allowing for refurbishment

- Fluid end configuration interchangeable with Scamont SP600

- Clear water or slurry service with solids up to 8mm in size

- Low R.P.M

- Simple maintenance procedure

- From 4.63 litres per second at 20.7 MPa to 10.42 litres per second at 9.55 MPa dynamic head

- Different materials of construction available in order to deal with a multitude of corrosive forces

- Electric or diesel motor driven

- Proudly manufactured in South Africa